Gasoil

A middle distillate and form of heating oil used primarily in heating and air-conditioning systems. One of the most actively traded oil products, gasoil is the underlying in a key International Petroleum Exchange (IPE) futures contract. In refining terms, gasoil comes between fuel oil and the lighter products such as naphtha and gasoline. In its broader definition, it covers the oil products used for diesel automotive fuel and jet fuel.

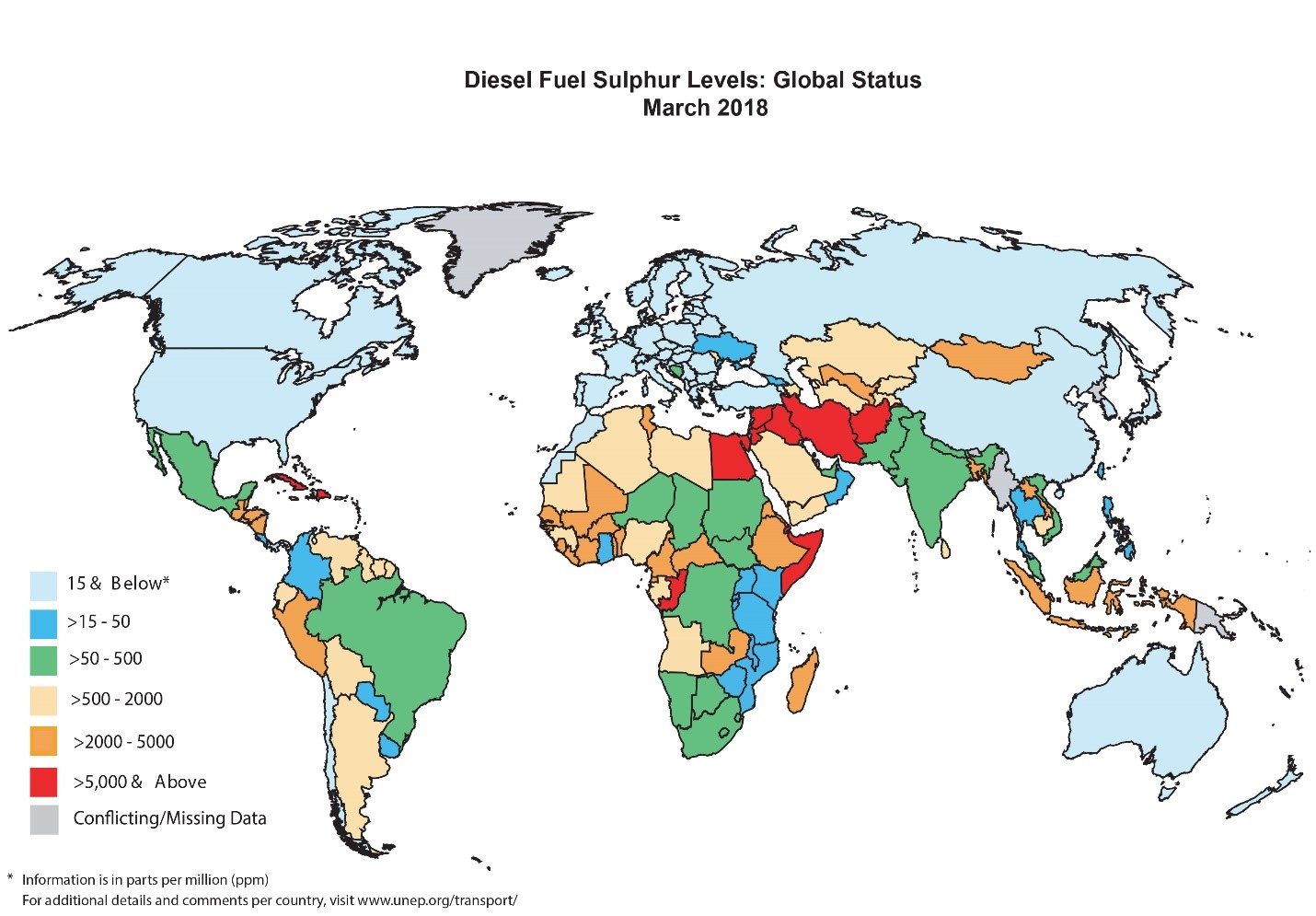

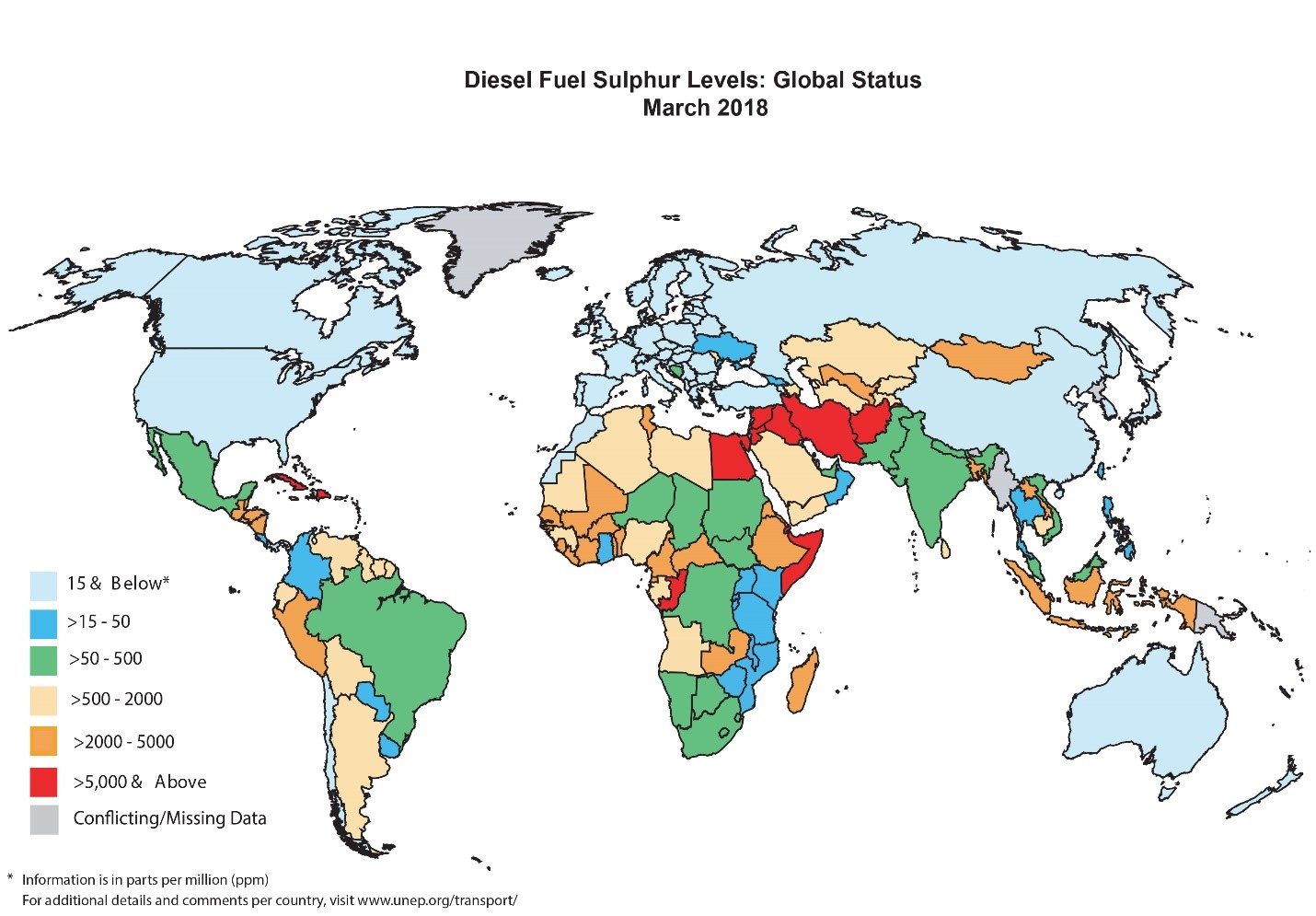

Diesel fuel contains sulfur which derives from the original crude oil source and can still be present after refining. After combustion in the engine, the sulfur in fuel forms particulates that are a primary contributor to air pollution and the cause of harmful corrosion in the engine. Regulations to reduce vehicle emissions over the past several decades have dramatically reduced the allowable sulfur content in diesel fuel.

Types & Specifications:

| SPECIFICATION -GASOIL 500 ppm |

| TYPYCAL TEST |

UNIT |

SPECIFICATION |

RESULT |

TEST METHOD |

| DENSITY AT 15 °C |

kg/ m3 |

REPORT |

826/8 |

ASTM D 1298 |

| FLASH POINT ,PMCC |

°C |

MIN 57 |

64 |

ASTM D 93A |

| KINEMATIC VISCOSITY AT 40 °C |

cSt |

MIN 1.9 -MAX 4.1 |

3/213 |

ASTM D 445 |

| TOTAL SULFUR CONTENT |

% Wt |

0/05 |

0/048 |

ASTM D 4294 |

| CLOUD POINT |

°C |

MAX 12 |

-6 |

ASTM D 2500 |

| DISTILLATION |

|

|

|

ASTM D 86 |

| 50% RECOVERY |

°C |

MAX 300 |

273/6 |

| 90% RECOVERY |

°C |

MAX 355 |

338/2 |

| 95 % RECOVERY |

°C |

MAX 370 |

355/3 |

| RCR ON 10% DISTILLATION RES |

% Wt |

MAX 0.30 |

<0.10 |

ASTM D 524 |

| COLOR |

|

MAX 3.0 |

L 0.5 |

ASTM 1500 |

| ASH CONTENT |

% Wt |

MAX 0.01 |

<0.01 |

ASTM D 482 |

| CETANE INDEX |

|

MIN 45 |

56/6 |

ASTM D 976 |

| COPPER CORROSION 3hr AT 100 °C |

RATING |

MAX NO.1 |

1a |

ASTM D 130 |

| WATER CONTENT |

% Wt |

MAX 0.05 |

<0.05 |

ASTM D 95 |

| LUBRICITY HFRR AT 60 °C |

MICRON |

MAX 530 |

518 |

ASTM D 6079 |

| AROMATICS |

% VOL |

MAX 35.0 |

21/1 |

ASTM D 1319 |

| SPECIFICATION -GASOIL 10 PPM |

| TYPYCAL TEST |

UNIT |

RESULT |

TEST METHOD |

| DENSITY AT 15 °C |

kg/ m3 |

836/3 |

ASTM D 1298 |

| FLASH POINT ,PMCC |

°C |

66 |

ASTM D 93A |

| KINEMATIC VISCOSITY AT 40 °C |

cSt |

3/7 |

ASTM D 445 |

| TOTAL SULFUR CONTENT |

% Wt |

0/001 |

ASTM D 4294 |

| COLD FILTER PLUGGING POINT |

°C |

-3 |

ASTM D 2500 |

| DISTILLATION |

|

|

ASTM D 86 |

| 10% RECOVERY |

°C |

241/9 |

| 50% RECOVERY |

°C |

294/1 |

| 90 % RECOVERY |

°C |

345 |

| END POINT |

°C |

366/1 |

| RCR ON 10% DISTILLATION RES |

% Wt |

<0.06 |

ASTM D 524 |

| COLOR |

|

L 1.0 |

ASTM 1500 |

| ASH CONTENT |

% Wt |

0 |

ASTM D 482 |

| CETANE INDEX |

|

60 |

ASTM D 976 |

| COPPER CORROSION 3hr AT 100 °C |

RATING |

1 |

ASTM D 130 |

| WATER CONTENT |

Ppm |

40 |

ASTM D 95 |

| LUBRICITY HFRR AT 60 °C |

MICRON |

381 |

ASTM D 6079 |

| Acid Number |

mg KOH/g |

0/02 |

ASTM D 1319 |

| SPECIFICATION -GASOIL 5000 PPM |

| TYPYCAL TEST |

UNIT |

TEST METHOD |

SPECIFICATION |

RESULT |

| APPEARANCE |

|

VISUAL |

CLEAR (NOT HAZY) |

CLEAR &BRIGHT |

| DENSITY AT 15 °C |

kg/ L |

ASTM D 4052 |

835-860 |

0/8202 |

| FLASH POINT |

°C |

ASTM D 93A |

62 MIN |

62 |

| CCR ON 10% DIST.RESIDUE |

% Wt |

ASTM D 189 |

0/1 |

<0.10 |

| DISTILLATION |

|

ASTM D 86 |

|

|

| RECOVERY AT 357 °C |

|

|

87 MIN |

96/5 |

| COPPER CORROSION 3hr AT 100 °C |

|

ASTM D 130 |

NOT WORSE THAN NO.1 |

1a |

| WATER CONTENT |

Vol % |

ASTM D 95 |

0.05 MAX |

<0.05 |

| SEDIMENTS BY EXTRACTION |

MASS % |

ASTM D 473 |

0.01 MAX |

<0.01 |

| ASH |

MASS % |

ASTM D 482 |

0.01 MAX |

<0.002 |

| ACIDITY (INORGANIC) |

Mg KOH/g |

ASTM D 974 |

NIL MAX |

NIL |

| ACIDITY TOTAL |

Mg KOH/g |

ASTM D 974 |

0.01 MAX |

0/03 |

| TOTAL SULFUR |

MASS % |

ASTM D 4294 |

0.5 MAX |

0/446 |

| POUR POINT |

°C |

ASTM D 97 |

MINUS 4 MAX |

<-21 |

| CLOUD POINT |

°F |

ASTM D 2500 |

46 MAX |

9 |

| COLOR |

|

ASTM 1500 |

2 MAX |

L 2.0 |

| SPECIFICATION - LOW DENSITY GASOIL |

| TYPYCAL TEST |

UNIT |

RESULT |

TEST METHOD |

| DENSITY AT 15 °C |

kg/ L |

0/8098 |

ASTM D 4052 |

| FLASH POINT ,PMCC |

°C |

61/0 |

ASTM D 93 |

| POUR POINT |

°C |

<-30 |

ASTM D 47 |

| KINEMATIC VISCOSITY AT 40 °C |

cSt |

1/332 |

ASTM D 445 |

| MERCAPTAN SULFUR |

Ppm |

<50 |

ASTM D 3227 |

| SULFUR CONTENT |

% Wt |

0/126 |

ASTM D 4294 |

| IBP |

°C |

175/4 |

ASTM D 86 |

| 10% |

°C |

188/3 |

| 30% |

°C |

199/2 |

| 50% |

°C |

219/5 |

| 90% |

°C |

301/5 |

| FBP |

°C |

344/7 |

| COLOR |

|

2 MAX |

ASTM 1500 |

| CARBON RESIDUE |

% Wt |

0/5 |

|

| CETANE NUMBER |

|

50 MIN |

ASTM D 976 |

| CORROSION 3hr AT 100 °C |

|

1a |

ASTM D 130 |